Industry & Production - Beck Pack

Surprisingly fast payback time

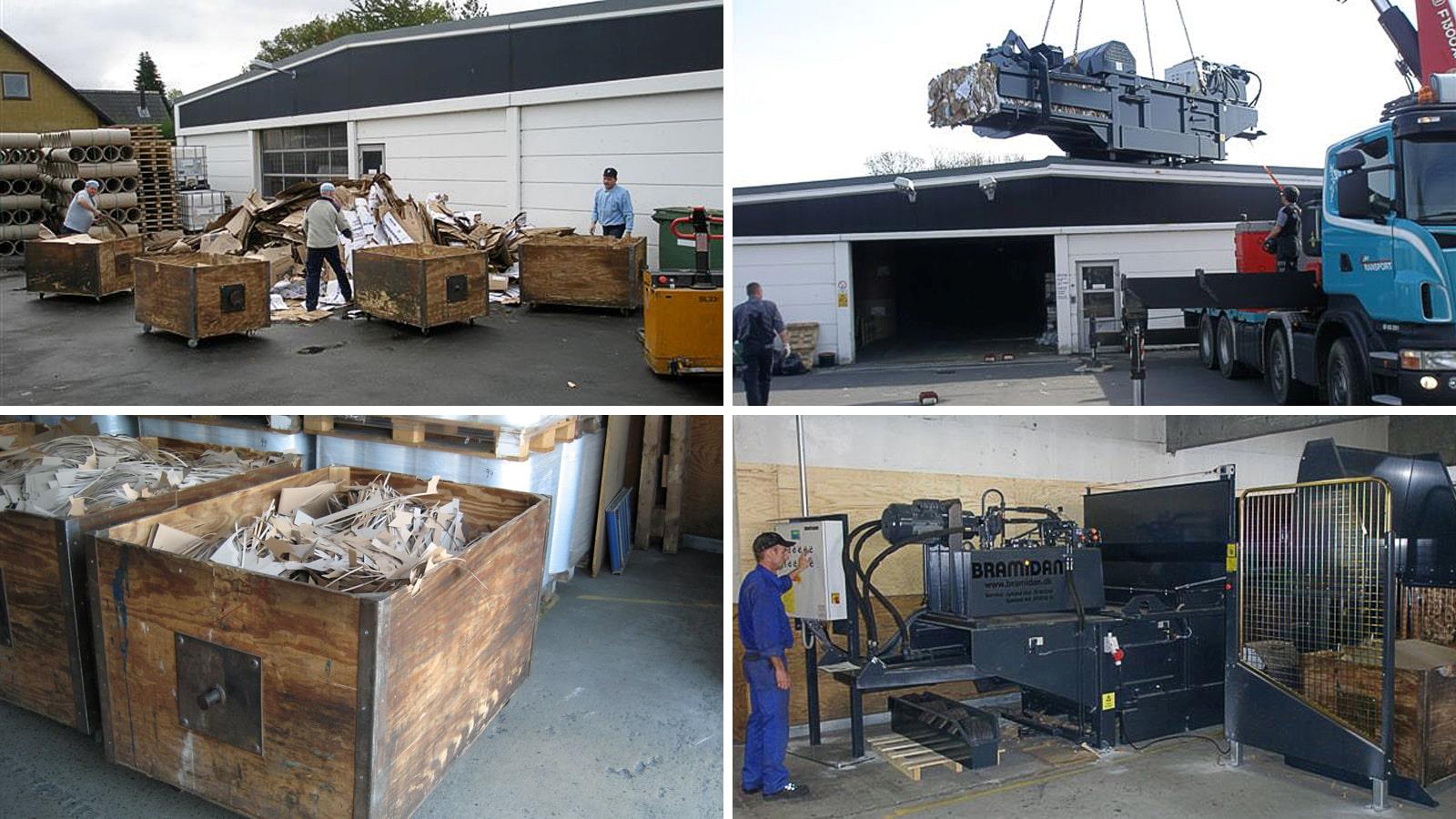

A high performance channel baler and a new logistics agreement have paid off for Beck Pack, who included Bramidan in their efforts to make their waste management more efficient.

Surprisingly fast payback time

Beck Pack is situated on the island of Bornholm in the Baltic Sea, and is one of the world’s leading suppliers of packaging for frozen goods, especially for the fish food industry. The packaging is used to store, for example frozen fish blocks which can be cut into fish fingers, and it must obey strict quality demands, in order to be used in food production.

Every year the company receives several thousand tons of recycled cardboard by lorry from Germany and France, turns it into packaging and ships it off again to destinations as far away as China, Australia and New Zealand. Back at the factory, large amounts of cardboard and paper waste need to be handled quickly and efficiently.

Calculations proved that daily collection was unnecessary

“We used to tip the waste into a 20m3 large container that was emptied every day. This cost us more than €13.500 a year. We also noticed that local contractors were interested in our cardboard waste, as they aimed to sell it for recycling”, says production manager Henrik Persson. Beck Pack then began to consider changing the company’s waste handling routines. A thought that quickly gained momentum when a sales representative from Bramidan suggested a baler.

“Bramidan calculated what a baler could contribute to our business and we also saw a new logistics concept, in which our German supplier of cardboard would pay for our cardboard waste. We saw that the new concept would enable a relatively short payback time for the baler, we eventually invested in.

Win-win situation with improved waste logistics

A horizontal channel baler, HC50, was installed in the spring of 2008. Beck Pack and Bramidan found the optimal place, as close to the production area as possible, and the baler has quickly proved itself to be a far better investment than first anticipated.

“Our waste handling and new logistics setup is much more efficient. We have also made agreements with other local companies to handle their cardboard waste, helping them reduce their costs and making a little money by selling it ourselves,” says Henrik Persson, who is in no doubt that Beck Pack is in a winning position.

“We have really won something. It is clear that the large investment has been very good for our business. We expected a payback time of slightly more than five years, but now we expect the investment to have paid for itself in three.”

Our waste handling and new logistics setup is much more efficient. We have really won something.

— Henrik Persson, Production Manager

If you have any questions, please contact us

phone +45 7517 3266

mail sales@bramidan.com

Looking for an alternative waste solutions?

See our full range

Fill in the form and we will contact you.